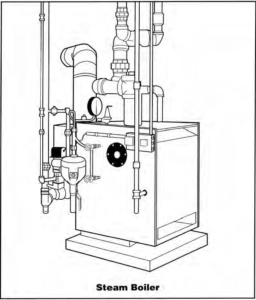

Steam Boilers

They’ve been with us for over two hundred years, and most of

the time they’re so reliable most folks don’t give them much

thought. They sit in buildings all over the world, transferring

heat from fuel to water, allowing us to warm our buildings or

complete our processes.

Steam boilers are simple, efficient and reliable. No machine

does a better job of moving BTUs from one place to another.

We’ve used them for space heating since before the United

States Civil War in 1861.

Even before the Civil War, we used steam boilers for industrial

processes. Today we use them to run factories, press clothes,

wash dishes, pasteurize milk, sterilize medical equipment,

and to heat entire cities! Their capabilities seem endless.

But despite its simplicity, any steam boiler can run into trouble

if its control system doesn’t act properly. If the energy you put

into the boiler exceeds what the boiler can absorb, the boiler

can rupture. So you must always be on guard.

A simple safety relief valve of the right capacity and relief-pressure

setting protects the boiler from over pressure. But over

pressure isn’t the only thing that can threaten a steam boiler.

There are also the dangers of dry firing.

Should the internal water level drop too low, the boiler can

burn out. So here too, you must always be on guard. You

see, a steam boiler needs its water to move the heat away

from its metal surfaces. Without the right internal level of

water, heat quickly accumulates. Too much heat creates a

very dangerous operating condition