How Does it Work?

Hot, High pressure continuous blowdown water drained from the boiler, contains valuable heat energy. The continuous blowdown process helps control boiler water quality and operating efficiency by removing suspended and dissolved solids from the water in the boiler drum.

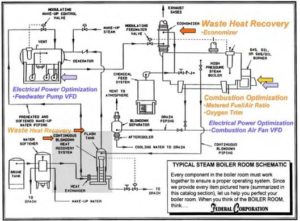

Recovery of up to 50% of the BTU’s available may be accomplished by generating low pressure flash stream in a flash tank. This supply of stream can be used in boiler D/A tank or other low pressure steam applications. As the flash steam is generated, the blowdown condensate that remains is used to preheat the boiler feed water using a low pressure liquid heat exchanger. For smaller, lower pressure blowdown requirements, the HX Series heat recovery system utilize a higher pressure liquid to liquid heat exchanger without a flash tank to do the heat recovery job. Contact a Federal sales representative will recommend the model you need to maximize your fuel savings potential.

- Recover 90% of the heat energy in continuous top blowdown that would be lost down the drain.

- Reduce temperature of blowdown discharge to drain to meet statute limits.

- Fast investment payback from fuel, cooling water and makeup water savings, Madden systems usually pay for themselves in less than 12 months.

- Durable, time proven designs, built to take the punishment of continuous, 24 hour a day service for years.